In the UAE, people test the trays to make sure they are strong and safe. This helps keep buildings working well. This is an obligatory stage of engineering quality control, which guarantees the stability of products to static and dynamic loads in various operating conditions.

Basic load testing standards

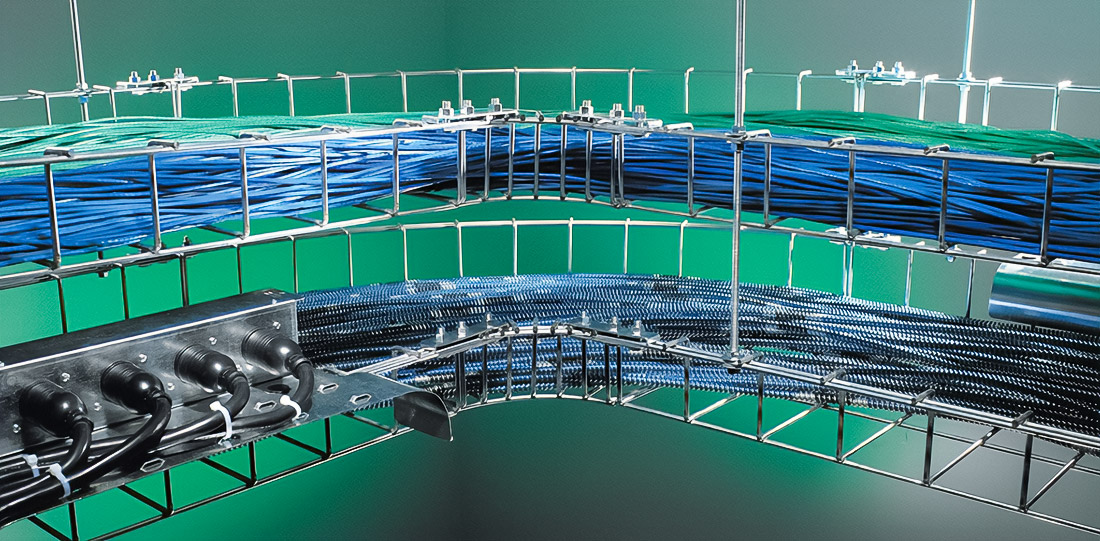

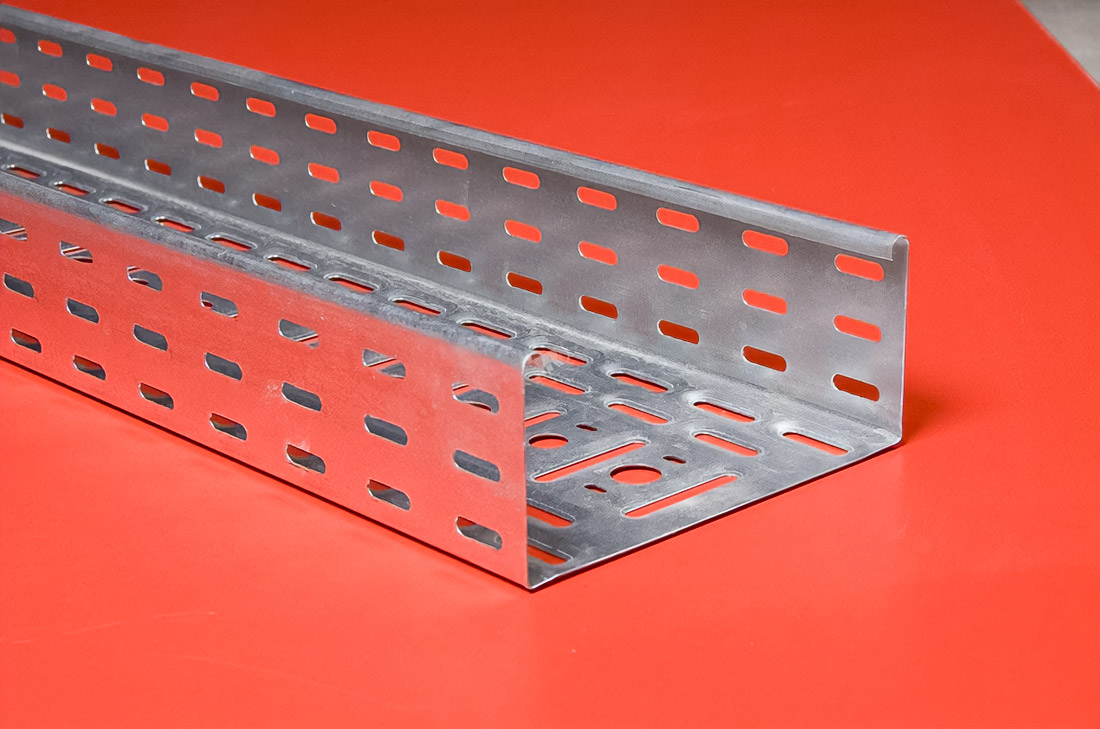

One of the most used standards is IEC 61537. It regulates methods for assessing the load capacity and stability of cable trays, including straight sections, turns, corners, and connecting elements. According to this standard, products are tested for bending, deflection, stretching and deformation under load.

There is a special rule called BS EN 61537. It tells people how to make cable trays strong and safe. It checks if the trays can stay strong in hot, wet, or salty places like near the ocean or in big factories.

Test practice from leading manufacturers

Large cable tray suppliers in UAE regularly conduct load tests according to the methods prescribed in the above standards. A typical procedure includes:

- Distribution of the standard test load over the entire length of the tray.

- Measurement of vertical deflection at a certain load.

- Checking the permissible deformation under constant load for a specified time.

- Comparison of the data obtained with the rated load capacity stated in the technical documentation.

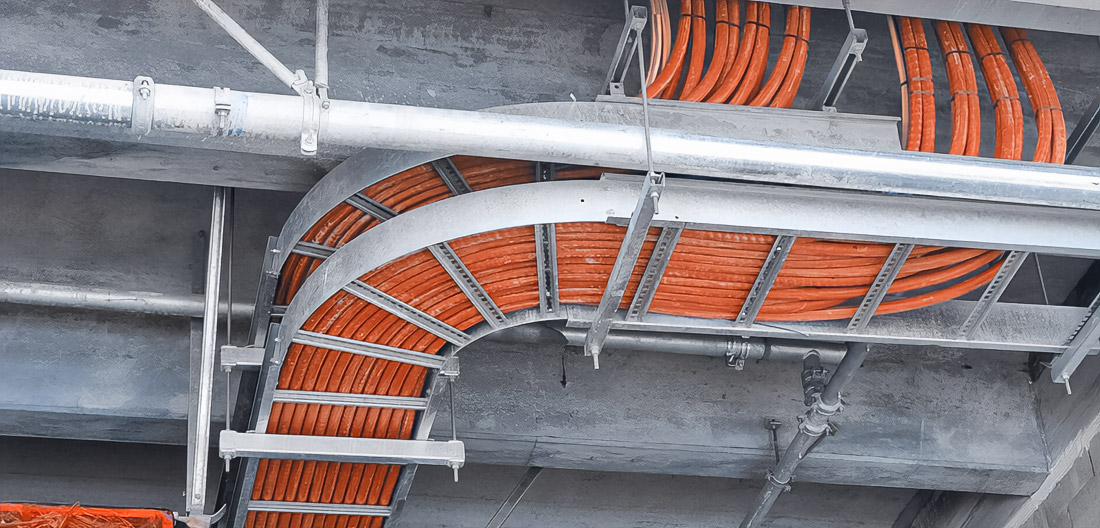

In most cases, testing is carried out on metal trays with a hot-dip galvanized coating according to ISO 1461, which guarantees corrosion resistance and meets the requirements for large industrial facilities in the UAE.

Why is this important for engineers and designers

Engineers working on projects in the energy, petrochemical, construction and transport sectors take into account not only the cost of products, but also their compliance with international standards when choosing suppliers. Failure to comply with the requirements of IEC 61537 or BS EN 61537 may lead to premature structural failure, risks of short circuits and accidents.

Special attention is paid to the ratio of weight and load capacity, as well as the stability of fasteners, especially in earthquake-prone regions or at sites with high vibration loads. Some cable tray suppliers in the UAE provide engineering test reports that include deflection graphs, load distribution diagrams, and photo reports.

Integration with BIM and design systems

Suppliers focused on working with engineering companies develop specifications and test protocols compatible with CAD and BIM environments. This allows specialists to immediately take into account the parameters of strength and reliability in the design models.

Conclusion

Choosing cable tray is not just about choosing the standard size or coating. This is an engineering solution that must be justified by calculations and confirmed by tests according to international standards. Competent cable tray suppliers in UAE provide not only the supply of products, but also technical support, test reports and consultations on load capacity. This approach makes it possible to ensure the safe and long-lasting operation of engineering systems.

Hiking addict, ramen eater, fender owner, Saul Bass fan and javascripter. Acting at the fulcrum of beauty and computer science to give life to your brand. My opinions belong to nobody but myself. Tropical swift lover.